No products in the cart.

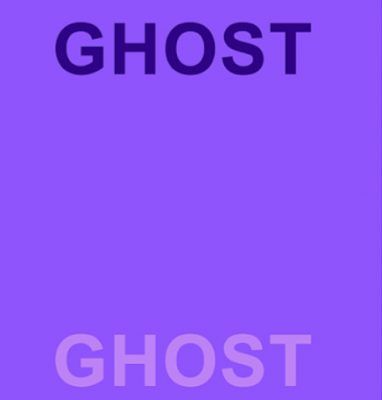

Ghosting in offset printing refers to a printing defect where faint or unwanted images or patterns appear on the printed material in areas where they should not be. These ghost images are typically lighter and less distinct than the intended image and can create an undesirable and unprofessional appearance on the final printed piece. There are three types of ghosting in offset printing: mechanical, chemical and blanket.

Ghosting In Offset Printing

There are several factors that can cause ghosting, including:

1. Ink and Water Imbalance: One of the common causes of ghosting is an imbalance between the ink and water on the printing plate. If the water fountain solution or dampening system is not correctly calibrated, it can lead to areas of the plate retaining unwanted ink, resulting in ghost images.

2. Press Setup Issues: Incorrect press setup, such as improper roller settings, inconsistent ink distribution, or inadequate blanket pressure, can contribute to ghosting.

3. Paper Properties: The type and condition of the paper used for printing can also influence ghosting. Some papers may be more prone to this issue due to their absorbency and surface characteristics.

4. Ink Properties: The characteristics of the ink being used, including its viscosity and tack, can affect the likelihood of ghosting.

5. Blanket Wear: Worn or damaged printing blankets can transfer ink unevenly, leading to ghosting.

6. Bad Roller Setting

To prevent and correct ghosting in offset printing, it’s essential to maintain proper ink-water balance, ensure that the press is set up correctly, use suitable paper and ink, and regularly inspect and maintain press components. Properly clean and maintain the ink rollers and blankets to prevent buildup and ink contamination. Use oscillating rollers, try changing the latitude that they are allowed to move.

If ghosting issues persist or are challenging to resolve, consider consulting with printing industry experts or technicians who specialize in offset printing.

Preventing ghosting in offset printing requires a combination of proper equipment maintenance, process control, and attention to detail. Regularly reviewing and optimizing your printing processes can help minimize the occurrence of ghosting and improve print quality.

(The article is for reference only)

Tiếng Việt

Tiếng Việt