No products in the cart.

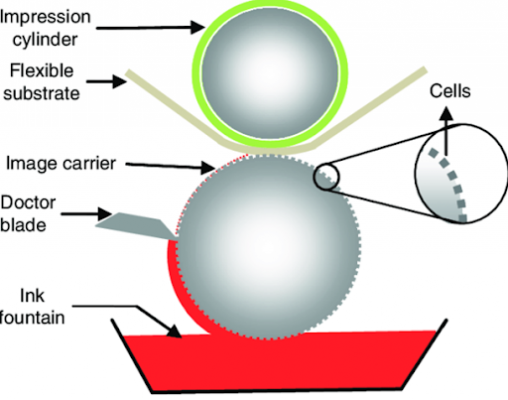

Gravure printing, also known as rotogravure printing, is a printing process that utilizes engraved cylinders or rollers to transfer ink onto a substrate. The rotogravure printing process does not use printing plates but instead, the graphics are engraved directly into a metal cylinder. Large copper plated steel cylinders are engraved with the chosen design using a laser or diamond tipped stylus. The engravings are referred to as ‘cells’ and are etched in differing depths, with deeper cells providing more intense the color. A different cylinder is required for every color used. The cylinders are then submerged partially in the ink fountain that on rotation fills the recessed cells. A blade wipes excess ink from the surface of the cylinder before the ink is transferred from the cells onto the printing material.

For even coverage, the printing material is fed between the impression cylinder and gravure cylinder. The material is effectively sandwiched with force to push the ink out of the cells to give the best finish. After the ink is transferred, the printed substrate passes through a drying or curing system before proceeding to the next color cylinder. This process can use heat, evaporation, or UV light to set the ink and remove solvents.

The printed substrate may undergo additional finishing processes, such as cutting, slitting, laminating, or die-cutting, depending on the specific requirements of the final product.

It is commonly used for high-quality, long-run printing jobs such as packaging materials, labels, magazines, and decorative prints.

Advantages of Rotogravure Printing:

- High-Quality Output: Rotogravure printing offers excellent print quality, including sharp details, vibrant colors, and continuous tones. It is well-suited for demanding applications.

- Consistency: It provides consistent and uniform print results, making it ideal for long print runs.

- High Speed: Rotogravure printing is a high-speed process, making it efficient for large-volume production. Gravure printing uses quick drying solvent based inks to help speed up the print process.

- Wide Substrate Compatibility: It can print on various substrates, including paper, plastics, foils, and films.

- Gravure cylinders are extremely durable, can be used for several print runs, as long as they are used regularly and can be maintained.

Disadvantages of Rotogravure Printing:

- High Initial Setup Costs: The production of engraved cylinders can be expensive, making it less cost-effective for short print runs.

- Limited Flexibility: Changing designs or colors may require producing new engraved cylinders, which can be time-consuming and costly.

- Environmental Concerns: Rotogravure printing can generate more solvent emissions compared to some other printing methods, raising environmental concerns.