No products in the cart.

The dampening roll in offset printing plays a critical role in the offset lithographic printing process.

Its primary function is to apply a controlled layer of dampening solution or water to the non-image areas of the printing plate. The dampening solution serves several essential purposes, and the dampening roll’s performance has several significant effects on the overall printing process and print quality:

1. Ink Repulsion

One of the most important effects of the dampening roll is that it keeps the non-image areas of the printing plate moist. This prevents ink from adhering to these areas, ensuring that only the image areas accept ink. Without proper dampening, ink could spread and smudge, leading to poor print quality and possible paper jams.

Dampening Roll – compound J-Square của Techno Roll

2. Ink-Water Balance

The dampening roll helps maintain the delicate balance between ink and water on the printing plate. Achieving the right balance is crucial for producing sharp, clean prints. If there is too much dampening solution, it can dilute the ink and result in a washed-out appearance. Conversely, too little dampening can cause ink to build up on the non-image areas, leading to print defects.

3. Print Quality

The even and controlled application of dampening solution by the dampening roll is vital for achieving high-quality prints. It contributes to image sharpness, color fidelity, and detail reproduction. Proper dampening ensures that the ink adheres to the image areas precisely, resulting in clear and vibrant prints.

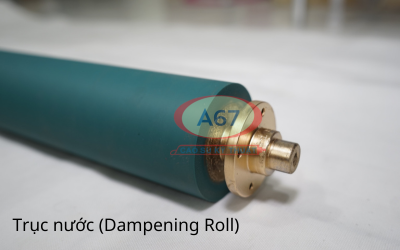

Dampening Roll – compound of A67

4. Paper and Substrate Compatibility

Different types of paper and substrates have varying absorbency levels. The dampening roll must be adjusted to accommodate the specific substrate being used to ensure optimal print quality. Softer rollers are often used when printing on highly absorbent materials.

5. Print Speed

The dampening system, including the dampening roll, must work effectively at different print speeds. Proper dampening is crucial for maintaining print quality when running the press at various production speeds.

6. Reducing Plate Wear

Maintaining the dampening system correctly can help prolong the life of the printing plate by reducing plate wear and minimizing ink buildup in non-image areas.

In summary, the dampening roll in offset printing has a profound impact on print quality, ink-water balance, and the overall performance of the printing process. Properly maintained and calibrated dampening systems are essential for achieving consistent and high-quality offset prints